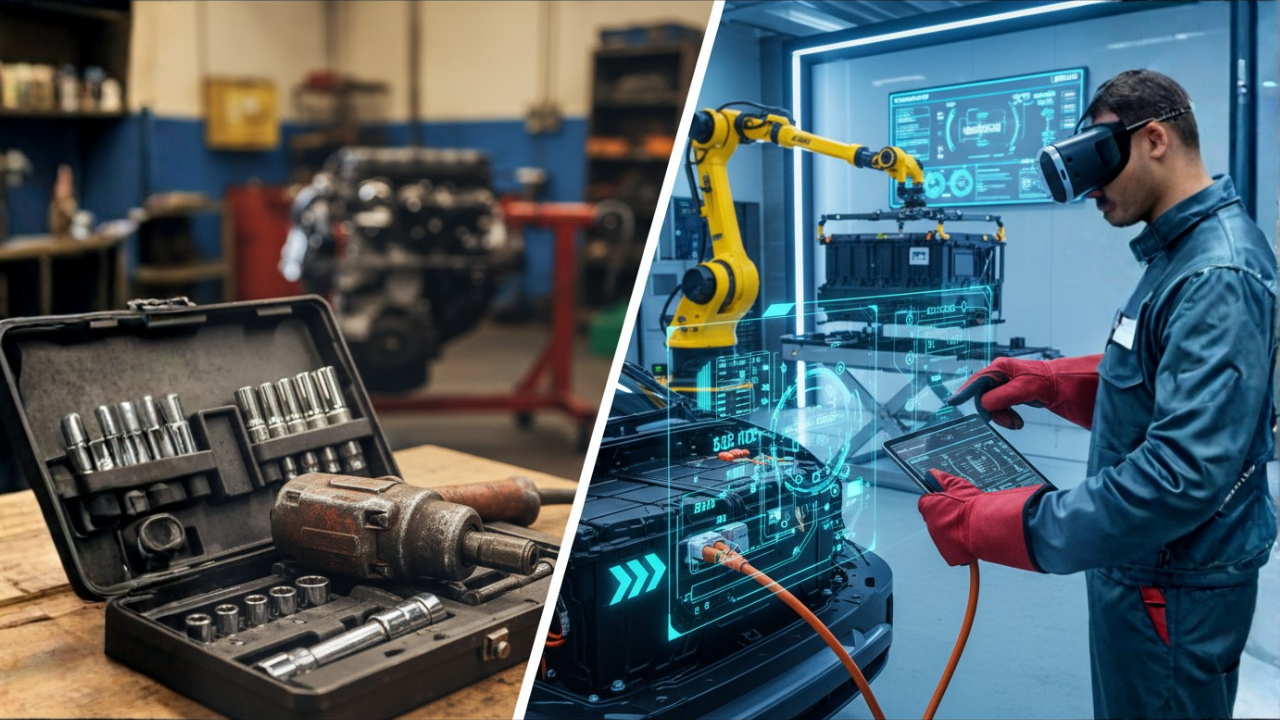

For decades, the heart of the auto workshop has been the familiar sound of a rattling impact wrench and the satisfying click of a socket set. But the automotive world is undergoing its biggest change in a century, and the tools we use are changing right along with it.

Cars are no longer just mechanical machines; they are sophisticated, rolling computers powered by everything from gasoline to high-voltage electricity. So, what will the toolbox of the near future look like? Let’s explore the key trends that will define the workshop of 2025-2026.

Trend 1: The Electric Revolution Hits the Toolbox:

The shift to Electric Vehicles (EVs) isn’t just a trend; it’s a fundamental rewiring of the industry. Servicing an EV requires a completely different mindset and, more importantly, a different set of tools. Safety and specialty are the new watchwords.

- Insulated Tools Are Non-Negotiable: Working with high-voltage EV battery systems is dangerous without the right gear. We’ll see insulated hand tools (wrenches, screwdrivers, and pliers) with a 1000V rating become standard issue in every bay. This is no longer a luxury; it’s a critical safety requirement.

- Battery Handling Equipment: An EV’s battery pack can weigh over 1,000 pounds. Hydraulic battery lifting tables and specialized support fixtures will become as common as the traditional engine crane, allowing technicians to safely and precisely remove and install these massive components.

- EV-Specific Diagnostics: The simple OBD-II scanner won’t cut it. Technicians will need advanced diagnostic tools capable of analyzing battery health, state of charge, individual cell performance, and the complex software that manages the entire system.

Trend 2: The Garage Gets Smart with Digital Diagnostics:

As every new car incorporates more technology—from Advanced Driver-Assistance Systems (ADAS) to intricate infotainment units—the real challenge is often diagnosing the software, not just the hardware.

- Augmented Reality (AR) Overlays: Imagine pointing a tablet at an engine bay and seeing a digital overlay that highlights the exact bolt you need to remove, shows the proper torque specs, or walks you through a complex wiring diagram. AR systems are moving from sci-fi to reality, promising to reduce repair times and minimize errors on complex jobs.

- “Do-it-for-me” Diagnostics: Scanners are becoming more than just code readers. The next generation of tools will not only tell you what’s wrong but also access vast online databases to provide step-by-step repair guides, TSBs (Technical Service Bulletins), and even video tutorials directly on the device.

- Calibration is King: With ADAS features like lane-keep assist and adaptive cruise control, a simple windshield replacement or wheel alignment now requires precise sensor recalibration. Workshops will need dedicated ADAS calibration frames and software to service these systems safely and accurately.

Trend 3: Everyday Essentials, Evolved:

Not all innovation is about EVs and software. The classic tools every mechanic relies on are also getting smarter, stronger, and more user-friendly.

- The Cordless Takeover is Complete: The debate is over. Battery technology has advanced so much that cordless tools now match or even exceed the power of their air-powered counterparts. Look for more compact, powerful, and efficient brushless motors in everything from impact wrenches to grinders, giving technicians more freedom to move around the shop.

- A Focus on Ergonomics: A mechanic’s career is physically demanding. Tool manufacturers are putting a major focus on ergonomics—creating lighter tools with better balance and vibration-dampening features. These small changes reduce fatigue and the risk of long-term injury, keeping experienced technicians on the job longer.

The workshop of tomorrow is a blend of old and new. It requires a technician who is part classic mechanic, part IT specialist, and part electrical engineer. The tools are evolving to meet that challenge, becoming safer, smarter, and more powerful than ever before. Is your workshop ready?